“This is a great way to make an easy installation where we reduce the carbon emissions

– Lucas Krogh Hansen, Head of Sales – Heat Recovery

and where we optimize the operational cost for the company.”

Project description

Reduce energy consumption with plug-and-play heat recovery

When Riedmair – a renowned industrial bakery north of Munich – set out to optimise energy consumption across its entire production, the answer was clear: invest in advanced heat recovery. The goal was to significantly reduce energy use while supporting a more sustainable production of bread and pastries.

With the ovens as the primary source of excess heat, the intention was to harness this thermal energy to generate hot water for internal processes and cleaning.

The solution was the installation of four Integrated HeatX Units (IHXU) – a plug-and-play system that gave Riedmair a fast, efficient, and future-proof path to major energy savings.

The customer

Uncompromising quality and craftsmanship

Riedmair is a third-generation family-owned industrial bakery based north of Munich. The company is known for its uncompromising focus on quality and craftsmanship: all bread and pastries are made without additives or premixes and always using carefully selected regional ingredients.

Combining traditional baking methods with modern production facilities, Riedmair is a strong player in both the retail and wholesale markets. With a clear focus on innovation and sustainability, the company is actively working to reduce energy consumption and CO₂ emissions – taking responsibility for both customers and the climate.

Solution specifications

Integrated HeatX Units (IHXU)

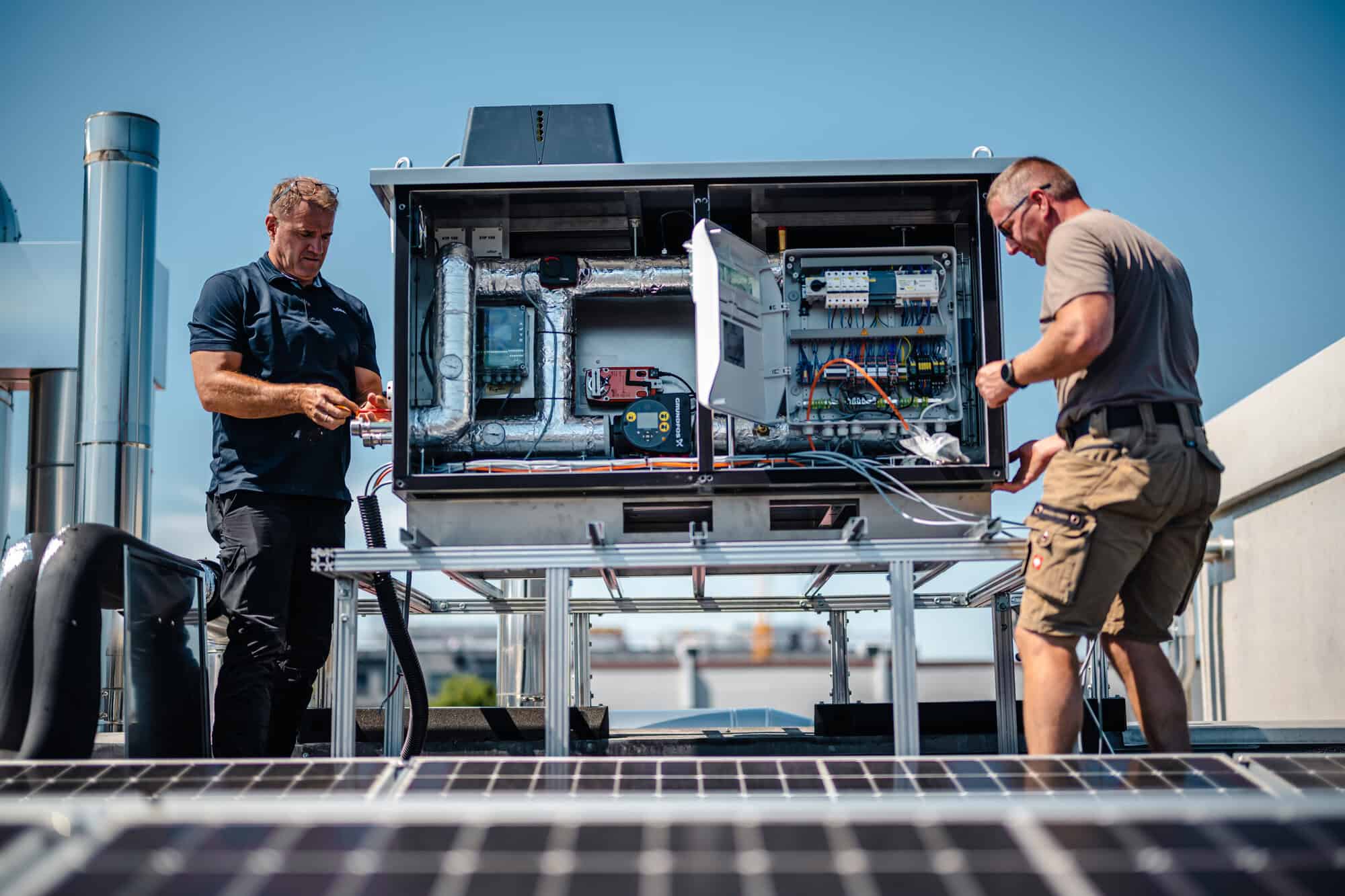

At Riedmair, four Integrated HeatX Units (IHXU) were installed – a fully integrated plug-and-play heat recovery system, where heat exchanger, water system and PLC control are combined in a single compact unit. This all-in-one design ensures simple installation and reliable operation, with minimal production downtime. The system requires only connection to water and electricity before it’s ready to run.

The four IHXU units capture large volumes of waste heat from the bakery’s ovens and convert it into hot water, which is used directly in production processes and for cleaning. In addition, the technology provides the option to transfer excess energy to local heat distribution networks – increasing flexibility and opening up new revenue opportunities.

The result is a solution that significantly reduces energy consumption and CO₂ emissions, while ensuring stable and cost-effective operation. IHXU enables Riedmair to combine economic gains with a stronger environmental profile – without compromising on quality or reliability.

Handover and results

Significant energy savings and a clear reduction in CO₂ emissions

The installation was carried out with precision and in close coordination with Riedmair’s team, allowing the implementation to take place without disrupting daily operations. The entire job took just two hours – the four units were lifted onto the roof by crane and then connected to water and power. Focus was on a smooth and rapid commissioning, during which staff received a detailed introduction to the system’s functionality and day-to-day operation.

Shortly after commissioning, the bakery began seeing the effects: a steady supply of hot water, significant energy savings, and a clear reduction in CO₂ emissions. For Riedmair, the solution delivers not just financial benefits, but also a stronger brand in a sector where sustainability and efficiency are gaining increasing attention.

exodraft