“We and our clients are very satisfied with our cooperation with Exodraft. Their heat recovery solution is particularly suitable for large and medium-sized bakeries.

– Aidas Pushkunigis, Representative in Baltic states – Almeva

We have confirmed this by installing Exodraft equipment in several bakeries in Lithuania and Latvia.

Thanks to the fact that Exodraft supplies a bypass damper alongside the heat exchangers, both we and our clients can be assured that the heat recovery process will in no way affect the baking process.

And the Exodraft fans, which have been tested in our market for many years, ensure a consistent chimney draft in all seasons, which is especially important for the quality of baked products.”

project description

Waste energy turned into a concrete and measurable benefit for both economy and environment

In November 2024, a large bakery in Panevėžys, Lithuania, took a significant step towards more energy-efficient production. With two W&P tunnel ovens running almost continuously, enormous amounts of excess heat were being generated and previously lost. The ambition was clear: to harness this energy to produce hot water for the entire building, thereby reducing both costs and the CO₂ footprint.

The solution was a heat recovery system where the waste heat from the ovens is now directed to three buffer tanks, which in turn supply seven heat exchangers with different temperature settings. This ensures that the recovered energy is distributed precisely according to the needs of the various processes and installations in the building.

The results have exceeded expectations. In less than a year, the system has delivered almost 1,000,000 kWh of hot water, and the investment has already paid for itself faster than originally projected. The project is a strong example of how heat recovery can transform waste energy into a tangible and measurable benefit for both the economy and the environment.

the customer

Integration with existing BMS system

The project was carried out in close cooperation with Almeva and Santechprekyba, experienced partners in energy solutions for the food industry. Led by Marius from Santechprekyba, the bakery received not just a technical installation, but a fully integrated solution tailored to their specific needs.

A key factor in the success of the project was the seamless integration with the bakery’s existing BMS (Building Management System), allowing heat recovery to be controlled in harmony with other production processes. This holistic approach ensures maximum efficiency and a system that operates smoothly in daily use.

Since the installation, the bakery has expressed great satisfaction, highlighting the professional guidance and implementation, which made the transition to heat recovery simple and trouble-free.

Solution specifications

Flexible system with high performance and a short payback period

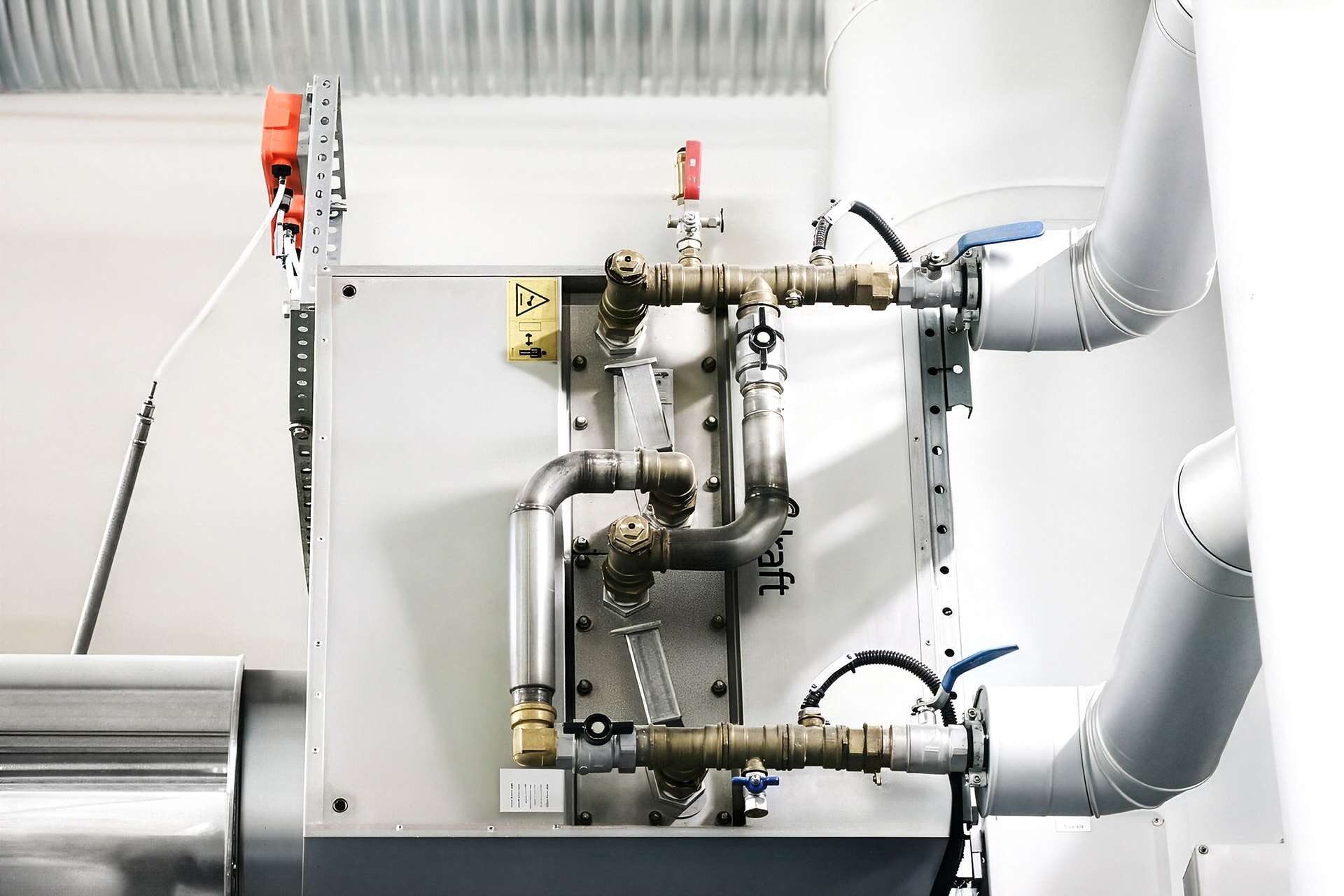

The heat recovery system in Panevėžys consists of several key components that ensure robust and efficient operation.

The main parts of the installation include:

The system is designed to capture the large amounts of excess heat from the bakery’s two tunnel ovens and convert it into hot water. This energy is stored in three buffer tanks, connected to seven heat exchangers. In this way, the hot water can be distributed to different parts of the building, each with its own temperature requirements – from cleaning and process water to heating.

The flexible design allows the system to adapt to variations in production and the different temperature needs throughout the building. At the same time, the entire installation is integrated with the bakery’s existing BMS, enabling central monitoring and optimization of operations.

The result is a solution that makes optimal use of excess heat and delivers documented savings – with nearly 1,000,000 kWh of hot water produced in less than a year, and a payback time already achieved within 12 months.

Handover and results

High customer satisfaction and professional implementation

The project in Panevėžys was realized through close dialogue between the bakery, Almeva, and Santechprekyba. The installation was carried out with a focus on operational reliability and system integration, so that heat recovery became a natural part of the production process from day one. Marius from Santechprekyba played a central role in the process and received high praise from the customer for delivering a fully optimized system and a smooth implementation.

The results speak for themselves: a solution that has already delivered almost 1,000,000 kWh of hot water, a payback period of just one year, and a significant reduction in energy consumption and CO₂ emissions. The bakery regards the investment as a success, particularly highlighting the system’s reliability and user-friendliness in daily operations.

The success in Panevėžys has also paved the way for expansion. The company has chosen to invest in a similar setup at their bakery in Vilnius, where Santechprekyba is leading a comprehensive energy project. Once again, heat recovery will play a central role in the solution, and the expectation is that the investment will deliver the same strong results – both economically and environmentally.

exodraft